Product Description

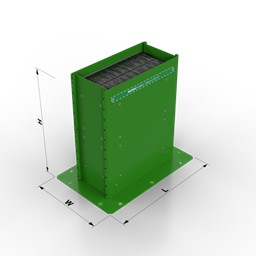

BOSS FyreBox™ Cast-In

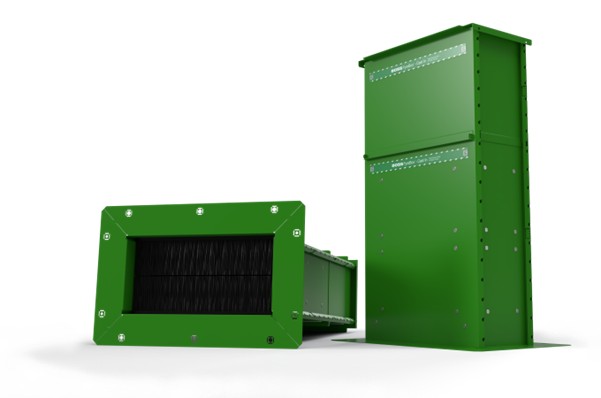

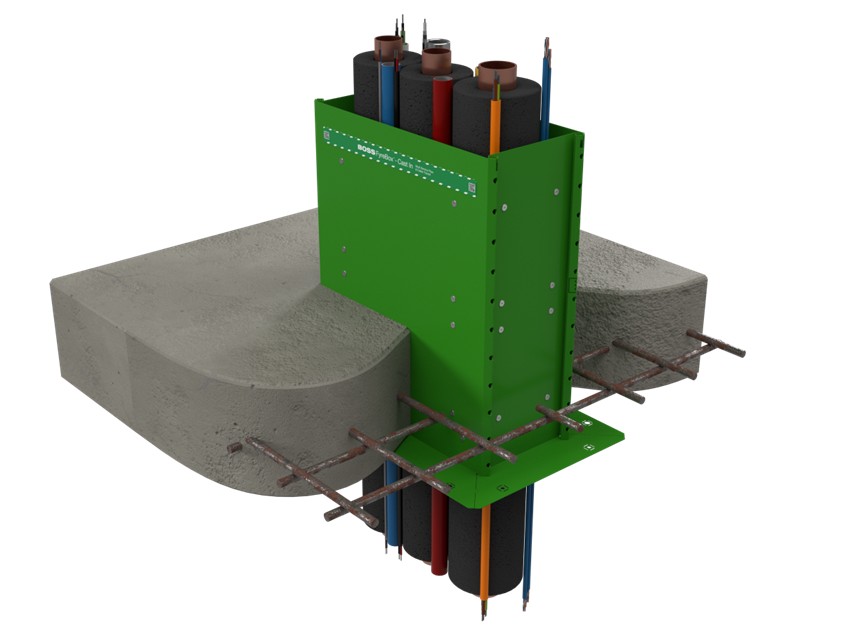

The BOSS FyreBox™ Cast-In is a multi-service cable and pipe transit device designed for firestopping bundled services through fire-rated concrete floor slabs. Engineered specifically for new construction, it is installed before the concrete pour, saving time, space, and eliminating the need for messy, costly concrete coring. By pre-planning the passive fire protection, the design eliminates compliance risks in shaft and riser applications.

Why Cast-In to the Slab?

- Pre-planning avoids compliance risks

- Saves time in construction

- Improved scheduling of trades

- Saves space by allowing mixed services to pass through one opening

- Avoids costly concrete core hole drilling

Key Features

- Specifically engineered to allow for all slab thicknesses with “off the shelf” extension sleeve.

- Unique brush system provides fast & easy installation of services

- Space to allow building movement in seismic areas

- Future proofing benefits to add services later

- FRL’s up to 4hrs (-/240/240)

- Approved to AS1530.4-2014 & AS4072.1-2005

- Widest opening size of any transit device on the market

- Makes AS 1851-2012 periodic maintenance inspections simple and reliable

- Large variety of electrical, plumbing & HVAC services certified

Applications

The BOSS FyreBox™ Cast-In is suitable for a wide variety of buildings where multiple services need to pass through a concrete floor slab. Typical projects include apartments, aged care, hotels & student accommodation buildings, services cupboards or shafts and risers in high rise buildings. The BOSS FyreBox™ Cast-In can also be used in industrial & commercial buildings such as factories, data centres, hospitals, and retail facilities. Typical bundles of services include:

- Steel & cPVC Sprinkler Pipes

- Copper Gas / Water Pipes

- uPVC DWV Pipes

- PEX & PEX-AL Water & Gas Pipes (Lagged & Unlagged)

- Air Conditioning / Paircoil Pipes

- Lagged & Unlagged PE-RT or PE-RT Kelox Pipes

- HDPE, PP & PP-R Pipes

- Copper, Steel, Stainless Steel & Ferrous Metal Pipes (Lagged & Unlagged)

- TPS Power Cables

- Orange Circular Mains & Sub Mains Cables

- uPVC Conduits

- Data / Comms Cables – NBN, CAT6, CAT5E, CAT7

- Coax Cables – CATV / MATV / SMATV

- Security, LAN, Fig 8, Fibre Optic, EWIS & Speaker Cables

- Aluminium Core Cables

Traditional Passive Firestopping vs BOSS FyreBox™ Cast-In

The BOSS FyreBox™ Cast-In has an extensive range of certified services tested and approved, that simply “pass through” the product.

By “casting in” the product at the time of the concrete pour, it removes unnecessary risk of improper product selection using traditional methods. There is no need to core individual penetrations for each service which is a costly and messy process. There is major labour savings compared with the traditional methods such as pillows, batts, sealants and collars.

The BOSS FyreBox™ Cast-In allows you to group various electrical, plumbing and HVAC+R services, all through one easy to use product. The unique BrushSeal™ allows services to be passed through the FyreBox™ Cast-In at any time during construction or after a project has been completed future proofing the building.

One simple system and the reduction of individual penetrations adds simplicity for maintenance contractors and building managers across the life of the project.

How Does It Work In Fire?

- The FyreBox™ Cast-In Features advanced, high pressure intumescent material around the internal perimeter of the metal chassis.

- Intumescent expands during a fire to seal voids around metallics & closes gaps left by melting combustibles.

- Forms a dense char for a high-performance fire seal.

- Includes the innovative BOSS Fire® BrushSeal™ for easier installation and compliance.

- Delivers industry-leading fire protection standards of up to 4hrs

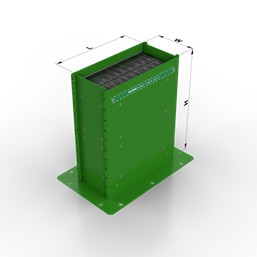

BOSS FyreBox™ Cast-In Size Selection

BOSS Fire developed a wide range of standard sizes off the shelf to avoid custom fabrication and costly lead times. Stocked items include:

| Product ID | Description | Internal Dimensions (mm) | External Dimensions (mm) |

| BFBCI-300 | BOSS FyreBox™ Cast-In 300mm | 300 (L) x 150 (W) x 400 (H) | 420 (L) x 270 (W) x 400 (H) |

| BFBCI-450 | BOSS FyreBox™ Cast-In 450mm | 450 (L) x 150 (W) x 400 (H) | 570 (L) x 270 (W) x 400 (H) |

| BFBCI-600 | BOSS FyreBox™ Cast-In 600mm | 600 (L) x 150 (W) x 400 (H) | 720 (L) x 270 (W) x 400 (H) |

| BFBCI-750 | BOSS FyreBox™ Cast-In 750mm | 750 (L) x 150 (W) x 400 (H) | 870 (L) x 270 (W) x 400 (H) |

| BFBCI-900 | BOSS FyreBox™ Cast-In 900mm | 900 (L) x 150 (W) x 400 (H) | 1020 (L) x 270 (W) x 400 (H) |

FyreBox™ Cast-In Extension Sleeves

BOSS have specifically engineered an “Extension Sleeve” that is simply slipped into place to extend the height of the FyreBox™ Cast-In in 200mm high increments to adapt to any concrete floor slab thickness.

| Product ID | Description | Additional Height |

| BFBCI-300-EX200 | FyreBox™ Cast-In 200mm Extension Sleeve – To suit BFBCI-300 | 200mm |

| BFBCI-450-EX200 | FyreBox™ Cast-In 200mm Extension Sleeve – To suit BFBCI-450 | 200mm |

| BFBCI-600-EX200 | FyreBox™ Cast-In 200mm Extension Sleeve – To suit BFBCI-600 | 200mm |

| BFBCI-750-EX200 | FyreBox™ Cast-In 200mm Extension Sleeve – To suit BFBCI-750 | 200mm |

| BFBCI-900-EX200 | FyreBox™ Cast-In 200mm Extension Sleeve – To suit BFBCI-900 | 200mm |

For complete peace-of-mind, choose the BOSS FyreBox™ Cast-In for ease of fire stopping installation, compliance & reliability.

For more information call our Technical Services team on 1300 502 677 to discuss your project requirements or follow the below links for more information:

FyreBox Cast-In Brochure FyreBox Cast-In Technical Guide Safety Data Sheet

Check out our traditional range of FyreBoxes to suit walls, ceilings and retrofit floor applications here:

Traditional FyreBox Range

For detailed approval information on the fire certification including service sizes, approved substrates and tested systems refer to Technical Documentation & Product Certification.

The BOSS FyreBox™ Cast-In must be installed in accordance with the manufacturer’s specifications or be subject of a Performance Solution.

Make sure you check your relevant Building Regulations, local laws and AS/NZS Standards to properly understand your obligations.

Each project and/or application may have specific requirements and you should investigate these carefully. Ensure that you have read and understood the appropriate certification relative to your needs, and ensure you seek acceptance from the Certifying Authority or compliance inspector before installation. Ensure the installation is carried out in accordance with the test certification, manufacturers instructions and in accordance with the relevant building codes and Australian Standards to your state or territory. For updates on the range of BOSS Fire® certification please contact BOSS Technical Services.

Product Details

Part ID & Dimensions

Recent Comments