BY SEAN CARROLL – ELECTRICAL CONNECTION MAGAZINE

Originally published in the Winter Edition of Electrical Connection Magazine 2021

Tradies can be held responsible if they break through a wall for cabling purposes and a fire occurs, even if the fire isn’t a direct result of their work. Sean Carroll finds out what this means for electricians.

I’ll set the scene: you’re doing all the electrical work for a company that has just moved into a new office block. Everything’s going fine, it’s all in order and there are no issues that can’t be fixed.

In the middle of the job, you realise you have to put a hole through a wall to pull some wires. So be it. When I say put a hole through the wall, I don’t mean some Hulk Smash level of hole, just enough to get what you need. Maybe even just a drill.

The job finishes, you get paid, go home and it’s all said and done.

Scarily, if a fire were to break out down the line, even if it’s not the fault of the electrical work, the electrician can be held accountable for breaking the passive fire protection of the wall.

BICSI South Pacific is a not-for-profit organisation which supports designers and installers of IT systems and promotes best-practice for quality and network integrity. But it also advocates the regulations and standards that keep people and property safe.

“The industry, our cabling industry and by extension of that, the electrical industry, even the plumbing industry has little knowledge of what’s required for fire protection,” BICSI South Pacific chief executive Paul Stathis says.

“It’s normal practice if you run services through walls, floors and between different areas of a building to punch holes in the walls. These can sometimes be designated fire containment barriers. This is quite acceptable, so long as the penetration is sealed in a way that retains that barrier’s fire resistance rating.”

As he goes on to say, these walls that electricians punch through can sometimes be known as ‘passive fire protection’ or ‘passive fire resistance’. By breaking through, they can limit the protective capabilities of the building and put it at risk.

For example, a concrete wall may be fire resistant for ‘x’ hours just by itself. This can be factored into the design of the building when looking at fire safety. If a contractor punches through the wall and leaves the hole exposed, the fire now has an avenue to jump through, spreading to the other side in a much shorter time than first expected.

“In my fire industry days, I spoke with a guy who had ended up in front of a coroner as a result of this,” Paul explains.

The person worked in a healthcare institution and there happened to be a fire at the place with a number of deaths. When speaking with Paul, he said that the coroner later on made him feel like he was personally responsible for the deaths.

He adds that the person is now working as a securities manager and is adamant about fire protection. He didn’t cause the fire, but he was held accountable because of some work he did well before the fire.

The person was even called to the witness dock in a coroner’s investigation – a place I can assume nobody wants to be.

Even if it’s not a fatal incident, the contractor can still get pinged a large sum of money.

“I want to get the message out there that prevention is far better than a cure,” Paul says.

The Fire Protection Association (FPA) Australia is the national peak body for fire safety, providing information, services and education to the fire protection industry and the community.

“Passive fire protection is complex and very often not understood. We attempt to help practitioners to understand how it should be used effectively to protect building occupants,” FPA Australia national manager, technical and advisory Leigh Gesthuizen says.

“One of FPA Australia’s technical advisory committees covers passive fire resistance. It not only advises on improvements to existing legislation, codes and standards, but uses industry knowledge to educate practitioners about how passive fire protection systems work and what protection they offer to occupants.”

Leigh adds that SA/CA009 Installation requirements for customer cabling (Wiring Rules) has provided legislation around this area and asks tradespeople to provide suitable and compliant protections of opening for cables.

“This clause was updated and improved in the current version of the standard to provide better clarity,” he says.

“In addition, section C of National Construction Code Volume 1 typically prescribes the fire resistance requirements for most buildings. Several clauses in this section apply to electrical work, most commonly clause C3.15.”

The FPA Australia has recognised this as an area that needs greater attention and is currently developing an awareness and training package specifically for cablers and electricians that will look into the principles of passive fire resistance.

Recently, it hosted a technical webinar presented by industry experts, with more education events planned for the future. “If you are unsure if a wall, floor, ceiling etc. is fire resistant or part of a smoke compartment, ask someone. If you don’t know how to protect it, engage a more experienced or qualified practitioner,” Leigh says.

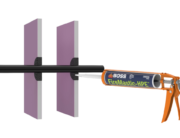

Fireproofing in the electrical industry: BOSS Fire Transit Box

Paul mentions how messy it can get when these incidents do happen. At the end of the day, “whoever makes the hole is responsible for it,” he says.

There are several products made specifically for this area and to suit a range of different types of wall material, installations and sizes.

A simple requirement that the NCC has is that when installing a product, it has to be tested and approved as an appropriate fire measure.

BOSS Passive Fire is a manufacturer of passive fire solutions, specialising in service penetrations. Its technical manager for, Australia and New Zealand, John Bacon, works with the relevant industries to answer technical questions and figure out how customers can best solve their passive fire stopping issues.

“With versatility in mind, we have developed a wide range of certified products that are compliant, quick, easy to install and cost effective for an extensive range of electrical service penetrations,” he says.

“We commonly see electricians and other trades miss critical details or make assumptions on how the product was tested or approved in relation to their planned use of the product. For example, because a product is tested on a concrete wall, doesn’t mean its approved for a concrete floor slab.”

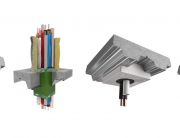

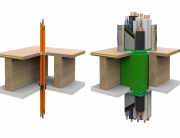

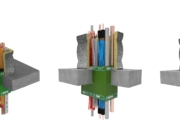

BOSS offers a range of fire sealants and silicones, thermal wraps and cavity barriers, along with the innovative BOSS Fire Transit Box which can be used through an extensive range of wall, floor or ceiling systems to give tradespeople a safe opening to pass through a variety of small and large mixed cable bundles, conduits, pipes and so on.

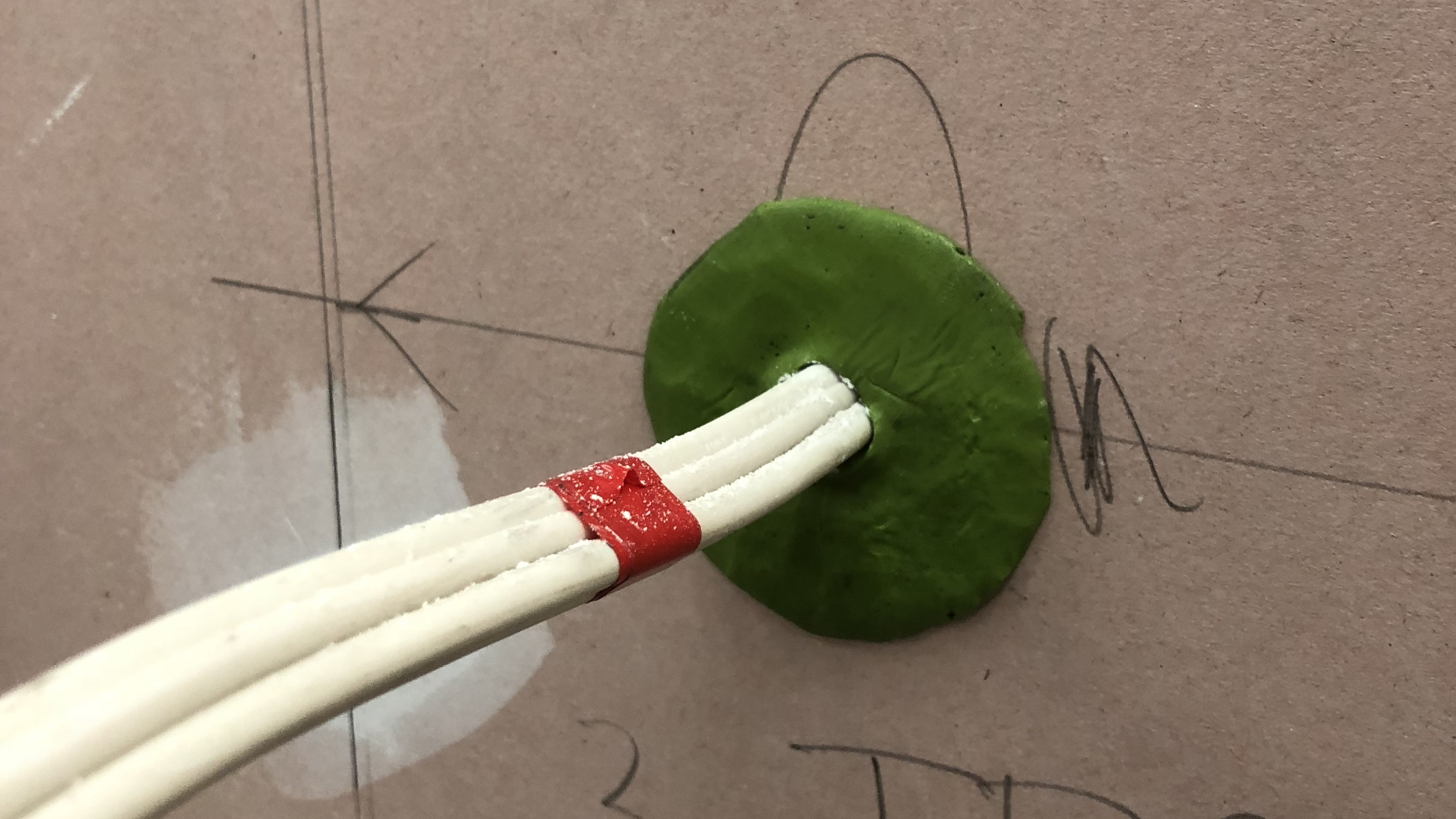

Other kinds of products include coated mineral wool boards, pillows and a fire rated putty which is installed after the surface has been broken to essentially repair the broken wall. BOSS Passive Fire has its own version, the PenoPatch, a small putty disc which is approved for small cable bundles.

Fireproofing in the electrical industry: BOSS Fire’s PenoPatch solution

“It only takes 30 seconds to install and provides a one-hour fire rating,” John says.

“It’s incredibly cost-effective and easy to keep in your van for when needed.”

John echoed what the FPA Australia and BICSI say, stating that once the installer understands that there is a form of passive fire protection needed, they need to ensure the correct product is being used.

“Once you think you’ve found the applicable product or system, get it approved by the site certifier for each different type of application before installation. It’s much easier and cheaper to gain approval first rather than re-building something after it’s been defected,” he says.

Key things to look out for in an installation are:

- Service type: what type are the cables, size and how many of them?

- Substrate or element and thickness: what is the substrate that the service is passing through?

- Size of opening or aperture: what is the size of the opening you need to seal up?

- Fire Rating: what is the length of fire rating?

“Documentation is everything,” Paul states.

If you’ve done the right thing, you want it to be written down that you followed all the appropriate steps: “Let’s say you’ve put a penetration in a fire wall. You’ve sealed it up and it happened five years ago. You need to put a document on there that says it was compliant with the building regulations at that time.

“A common misconception is that you can just throw in one of the fire protection solutions and Bob’s your uncle.”

So, harking back to the title of the article, deftly named after Billy Joel’s 1989 hit. Yes, We Didn’t Start the Fire, ‘we’ being the electricians in this case, but you may end up “trying to fight it” at the end of the day if the appropriate measures aren’t taken and regulations followed.

Please visit the FPA Australia website (FPAA.com.au) for more information on the topic.

Source: https://electricalconnection.com.au/fireproofing-and-what-it-means-to-the-electrical-contractor/

Recent Comments