High value properties – such as scientific research centres – always require careful planning to design the most effective fire safety protection systems. But when that property is 3,000kms away from the civilisation in one the harshest climates on earth, finding the absolute best system that’s sure to work when required, just gets more critical. Mark Prior, CEO of BOSS Passive Fire, discusses the challenges at Scott Base Research Centre in Antarctica.

As many experts and compliance inspectors would agree, its concerningly common to find buildings with less-than-acceptable planning in place for passive fire measures. The nuances of achieving passive compliance prove challenging to the installer; whether comprehending fire test approvals, selecting the right product for each application, or simply following installation methodologies correctly, the passive industry has long suffered from poor planning or ineffective installation.

One of the most common areas of non-compliance is in fire barriers where large bundles of mixed services, all passing through a single aperture with little, or no, effective protection. A common challenge then arises; how do you retrospectively reinstate fire separation when the building is occupied and services cannot be moved, changed or disconnected without major costly re-works or relocation of people?

The Scott Base research station in Antarctica has recently undergone a fire separation upgrade. It, too, had older buildings with the common fire separation problem. Read on to learn what can be learnt from this unique project.

Background

Scott Base, New Zealand’s only Antarctic research station, perches on a volcanic headland at the southern end of Ross Island. It is 3800km south of Christchurch and 1350km from the South Pole.

Scott Base serves as a strategic hub for scientists from New Zealand and across the globe to carry out some of the most important research in the world.

“Scott Base is vital for the future of New Zealand’s science programme and for our work with upholding the Antarctic Treaty system with 2019 marking the 60th year since it was signed. And, of course, Scott Base is part of our cultural history from when Sir Ed Hillary founded it in 1957″ said Foreign Affairs Minister Winston Peters.

The Problem

Scott Base opened in the late 1950’s, with most current buildings constructed in the 1980s, and the ‘Hillary Field Centre’ was finished in 2017. There are increasing points of failure; the buildings, materials and systems are deteriorating with age and reaching the end of their functional life, according to Scott Base Redevelopment senior project manager Simon Shelton.

FFP Canterbury, along with Paul Richards of Fire & Emergency NZ, was engaged to conduct a Fire report which identified the “poor state” of Scott Base’s passive fire protection elements, where both penetration seals and fire barriers were ineffective;

“The use of fire pillows as the primary source of fire retardant is inadequate and we would recommend that all fire pillows are removed and replaced with suitable fire rated surfaces and penetrations sealed appropriately with a single new system.” (Scott Base Fire Safety Report – FFP Canterbury)

Although typical of early measures of fire separation, the age of the existing building meant that effective passive fire planning was omitted from the design, as it was not a building requirement at the time of construction. The FFP Fire report found underfloor spaces were heavily congested with existing services and exposed high-level fire risks and design flaws.

“Most of the fire walls are only partially useful, with many barely offering a smoke separation as they stand and some offering no protection at all.” – (Scott Base Fire Safety Report – FFP Canterbury)

Challenges

Ideally, when upgrading existing buildings, it’s simpler to close a building and have the occupants relocate whilst works are underway. This would allow services to be decommissioned, and relocated if necessary, to enable effective penetration seals to be installed. At Scott Base, this wasn’t possible due to the remote and critical nature of the ongoing operation.

Apart from the permanent nature of the building’s operations and need to be staffed, Scott Base presents several significant and unique risks in terms of fire safety. Spread of fire, particularly from inadequately fire-separated storage areas off long corridors, is a significant exposure. Existing fire procedures would mean evacuating occupants to some of the harshest weather on the planet, where outside temperatures drop as low as -57°C and winds reach 180km/h, creating as much safety risk outside the building as within.

The remote location naturally provides additional risk, where it’s critical that the safety measures operate correctly and effectively, every time. While there is a well-trained fire crew on standby 24/7, the luxury of a well-equipped, metropolitan fire brigade arriving within minutes to save the day, clearly doesn’t exist in Antarctica.

The obvious logistical challenges, including extreme isolation and difficulty transporting equipment and supplies, means for longer delivery times to Antarctica. Product availability impacts project time frames, scheduling and working conditions for trades, not to mention the extreme temperatures building products are exposed to in transit. For goods damaged in transit or ruined from the extreme temperatures, it’s a long wait for replacements.

Solution

The Fire Safety Report initially recommended a traditional methodology of fire stopping, involving fire rated sealants and pipe collars that penetrate a compressed rockwool batt system – but this system would require separation of services to be treated individually – a significant physical challenge on this project. It’s worth noting that, being a NZ-managed research centre, the fire stopping system was designed under the requirements of AS/NZS 1530.4 and AS/NZS 4072.1

Potter Interior Systems – the NZ division of CSR Building Products and leading supplier of Passive Fire Products, proposed an alternative solution. Working with FFP Canterbury, and later Dominion Contractors and Fire & Emergency NZ, they presented a relatively new concept for managing multiple bundles of mixed services – the BOSS Fire Transit Box.

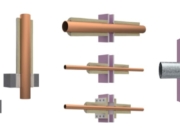

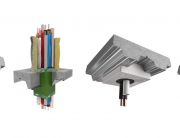

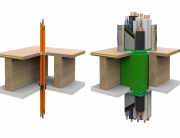

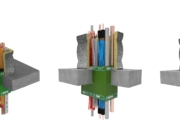

The concept of BOSS’s multi-service transit boxes has revolutionised the firestopping concept for applications with large bundles of services in confined spaces; such as data centres, apartment entry and underfloor cable ducts, where all services are bundled together, passing through a single aperture. Made from a steel outer chassis with high pressure exerting intumescent sash inlay’s that expand in a fire scenario, the transit box concept then closes off the aperture around all the different services, protecting and insulating for up to 120mins. Electrical and comms cables, a wide variety of plastic and metal pipes suitable for plumbing, and HVAC services such as lagged Airconditioning and hot water pipes are all examples of services that have been tested to pass through a single transit box.

The benefits of BOSS’ multi-service transit box suit remote and risky projects like Scott Base. As the box houses all nature of services, it’s difficult to get the installation wrong. Fixing is simple, and once the material type and size of each service is ticked off on the list of tested services, it’s simply a matter of passing the service through the box. Over a building’s life cycle, service requirements can change with the changing use of a building, potentially needing to add or delete services at later stages. The nature of changes to traditional passive fire systems requires new penetrations and treatments, which is often carried out by trades who aren’t aware of the fire protection requirements. This brings an inherent risk when disturbing a sealed system and not reinstating the integrity of a tested, approved system.

Multi-service transit boxes, however, require no structural changes or disturbance to add or delete future services. This ‘future proofs’ a project, saving time and reducing risk. On that basis, Potter Interior Systems were contracted to supply the BOSS FyreBoxes to Scott Base as part of the overall passive fire upgrade works.

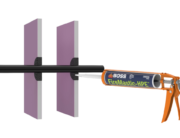

BOSS FyreBoxes were used to retro fit and feed new and existing services through the fire rated transit boxes. The boxes were installed in conjunction with the high-performance fire sealant, BOSS FireMastic-300™, to create safe fire-cells and remove redundant legacy passive fire products, such as fire pillows.

Scott Base presented another good reason to think carefully about unseen risks. With the design complete and fire testing carefully analysed, there was still a major hurdle to jump; temperatures in transit can reach -57°C. Temperature-controlled vessels can assist during shipping, but overland transport, once moving the products to site, was a major risk factor. Contractors had complained of sealants and mastics arriving on site frozen, meaning important products were ruined and unable to be used. The application of fire mastics is as critical as its performance, and when fire sealants are frozen and thawed, the water content separates, rendering the mastic unusable.

Fortunately, BOSS Fire had experience in shipping fire products into Scandinavia, where similar temperatures are commonplace. Creative packaging solutions were implemented, where BOSS’ other thermally insulative products were used to isolate cold in the same way they are normally used to protect from heat, and ultimately contractors were pleased when the FireMastic arrived in perfect condition, despite the sub-zero temperatures.

Result

Following the Fire Safety Report, FENZ developed a plan to bring the building into compliance with the Building Act using bespoke design and ‘verification of performance’. That work is now complete and the current base has been certified by FENZ to be compliant with the relevant sections in the Building Act.

That result included a future-proofed Passive Fire solution for Scott Base by retro fitting BOSS FyreBoxes and Cable Transits to existing services, providing a seamless integration and installation process. Ultimately, a solution to protect life was implemented by providing the safe passage and effective fire separation and evacuation of 80+ patrons, should a fire occur.

To learn more about the BOSS FyreBox™: Click Here

Or to learn more about the BOSS Cable Transit CT120 & CT240: Click Here

Download Scott Base Case Study

Tags and credits

Download the Scott Base Fire report here:

https://www.scribd.com/document/384666877/Scott-Base-fire-report#download&from_embed

Potter Interior Systems – Daryl Knowler – Passive Account Manager

Dominion Constructors Ltd – Stuart Montgomery

https://www.constructors.co.nz/scott-base-passive-fire-upgrade/

Source credits:

https://www.newsroom.co.nz/2018/07/25/165292/fire-report-exposes-scott-bases-flaws

https://www.constructors.co.nz/scott-base-passive-fire-upgrade/

https://www.beehive.govt.nz/speech/scott-base-redevelopment-announcement

https://www.beehive.govt.nz/release/design-selected-scott-base-redevelopment

Recent Comments